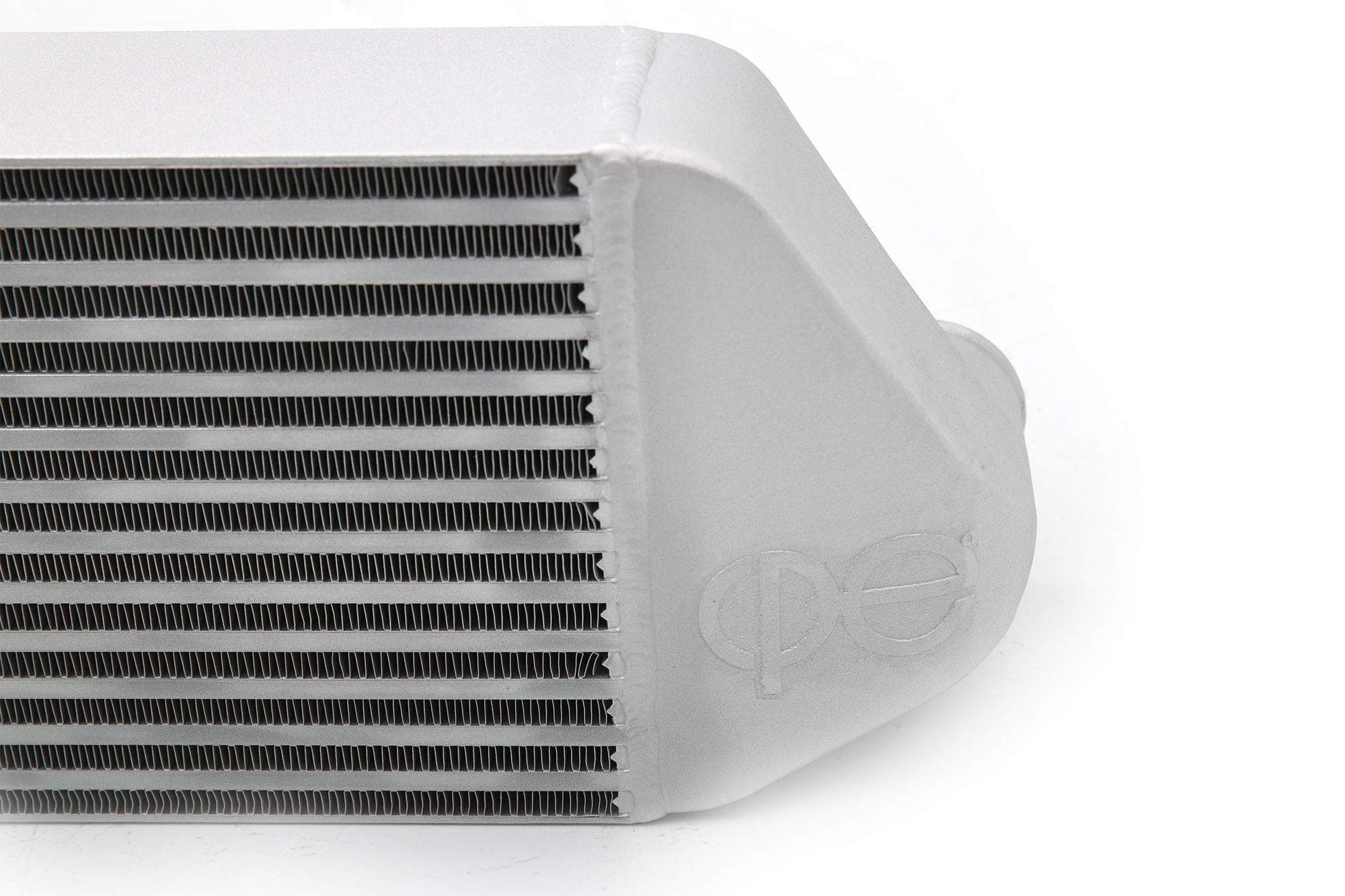

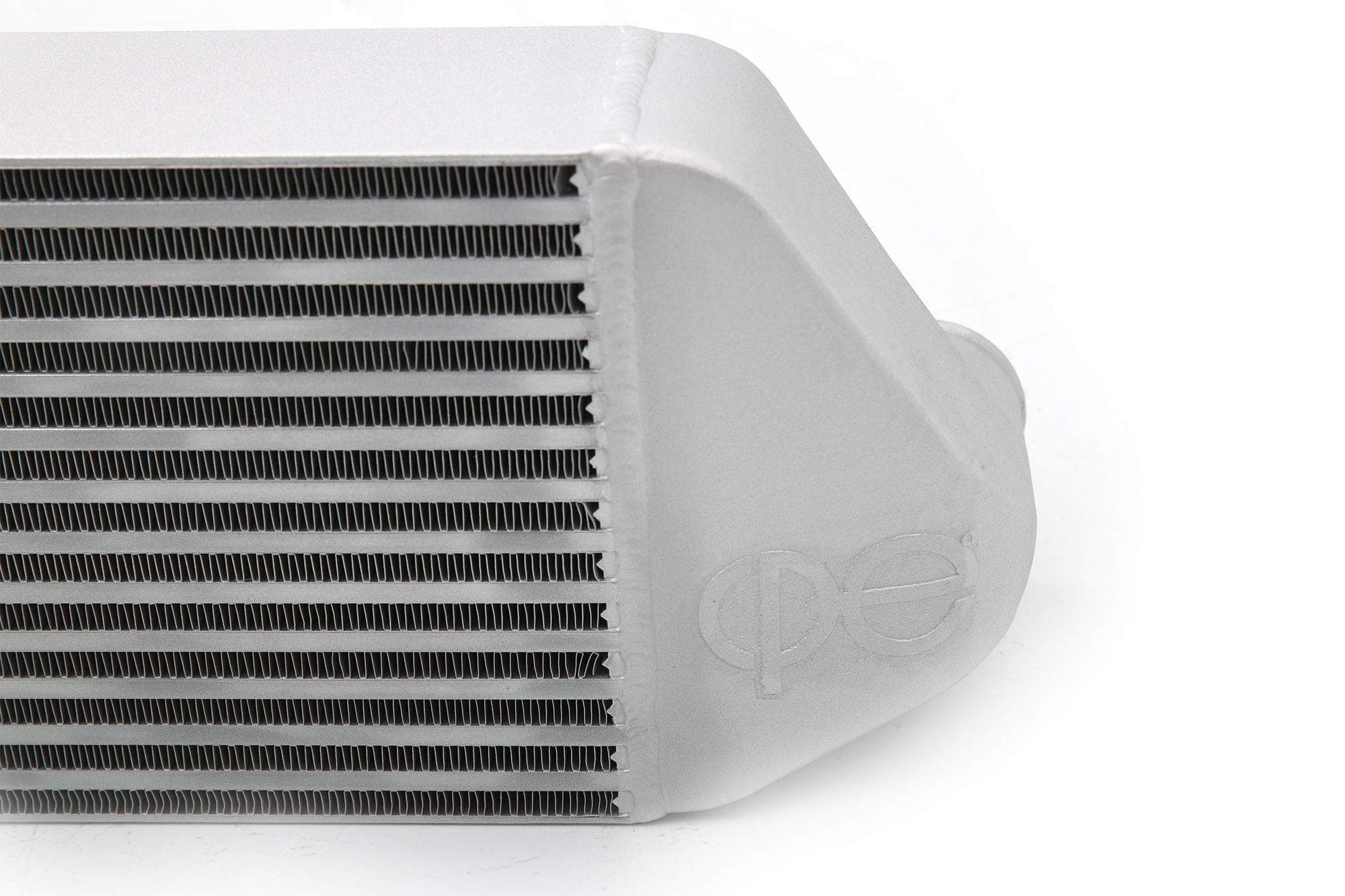

CP-E Delta Core Focus ST Lightweight Front Mount Intercooler

CP-E brought their engineering dedication and excellence to their Focus ST Lightweight Front Mount Intercooler (FMIC).

The stock intercooler does an excellent job for the everyday driver that doesn't want to modify their car. However, once you find that itch to go faster, the intercooler is a must have modification.

At Steeda Europe we independently tested a stock EU Focus ST when they were first launched and found that after a SINGLE power run on the dyno the stock intercooler was overwhelmed and the car would start to lose power on every run after that. So people who think that intercoolers are irrelevant, and that remaps, intakes and exhausts are all that matter are very much mistaken! Sure if all you want is a "single run pull" number that you can talk about on forums, then OK, but if you want actual repeatable, useable power on street or on track, then a high quality intercooler is a must in the Ford Focus ST mk3.

Features:

- Lightweight, highly efficient design

- Minimal Pressure Drop

- Maximized Core Design

- Substantially Lower & More Consistent Charge Temps

- Bolt-in Design, No Vehicle Modification Needed

- Fully Cast End-Tanks

cp-e started off by determining the maximum size core that could fit without major modification to the vehicle. After the initial large core, CP-E built a lightweight version that combines performance with a smaller footprint. What they ended up with is a 28" x 8.25" x 3.5" (711mm x 210mm x 89mm) core that performs great with lighter weight and a smaller size. This core uses the bar and plate design to help ensure a high level of efficiency.

If that's not enough for you CP-E also offer their serious "Big Boy" intercooler for the Focus ST, which is a huge 28" x 8.25" x 5.5" (711mm x 210mm x 140mm!)

Focus ST Lightweight FMIC Design

cp-e then set their sights on the end tanks, developing a design that not only encloses the core, but also requires no cutting, no drilling, and no permanent modification to the vehicle. With the laser cut brackets, the intercooler will mount in the stock location while matching up to the stock intercooler piping. Customers can now upgrade their piping when their power demands need it and modify in smaller increments.

As always, the cp-eintercooler includes cast end tanks that are welded and pressure tested with the core. What sets these endtanks from the rest is the engineering behind their shape and internal design. Hours of design and computer flow diagrams have been put into the tanks design to virtually eliminate turbulence within them. Many times, upgrading an intercooler causes increased turbo-lag, and an overall pressure loss. This is because of the large size of the core and the turbulence within the end tanks. By designing the end thanks to be smaller, and more efficient cp-e has found a way to minimize turbulence in order to keep the drivability of the car high, while still enlarging the intercooler drastically.

The internal design of the end tanks directs the air to bring the most optimal airflow as well as an even distribution throughout the core. In intercoolers, the back half of the core only does 25% of the cooling. The end tanks have been designed to direct the air properly into the core for the most even cooling, giving the vehicle the most consistent conditions going into the engine.

Ford Focus ST Lightweight FMIC Highlights

Turbulence Reduction Fins

When creating an intercooler, the goal is to maximize size, while not increasing pressure drop. Larger cores almost always exhibit some form of pressure drop, due to the massive turbulence in a large core. cp-e has engineered a way around this by adding our carefully calculated turbulence reduction fins to smooth out the airflow from the end tanks to the main core.

In the real world this translates to extraordinarily low pressure drop and no loss in spool times.

Fully Cast End Tanks

When durability and high horsepower are the main goals, nothing beats casting. Cut and weld sections just don't have close to the reliability of a cast piece. The problem is that casting is too expensive and out of reach for many manufacturers.

With the ultimate product as our end goal, we only accept fully cast end tanks for all of our front mount intercoolers.

Warranty Info

Steeda offer a limited lifetime warranty for material and manufacturing defects.

The warranty is for the original purchaser.

WHAT IS NOT COVERED

The following items are not covered under the Limited Warranty:

1. Failure or damage resulting from normal wear and tear, improper installation, repair, abuse, misuse, neglect, negligence, accidents, corrosion, or the alteration or modification of a part by the customer.

2. Failure or damage caused by work not performed by Steeda.

3. Failure or damage caused by a defective part or accessory not installed by Steeda main dealer.

4. Labour for the removal from a vehicle and reinstallation of a part or component sold “over the counter” or “over the internet.”

5. Service adjustments, such as calibration or alignments.

6. Rust or corrosion to parts caused by environmental conditions such as, but not limited to, salt or other caustic chemicals is not covered by Steeda's warranty.

7. Pitting is caused by brake dust, chemical abuse, or lack of maintenance and is not covered by Steeda's warranty.

8. Incidental or consequential damages. Steeda is not responsible for any time for which you may lose the use of your vehicle, any inconvenience you might be caused, the loss of your transportation or any part thereof, or any other incidental or consequential damages you may have.

GPSR Product info

Importer: Steeda Europe (Performance Imports BV)

Contact:

Postal Address: Choorhoekseweg 8, 4424 NW, Wemeldinge, Netherlands

Email address: info@steeda.co.uk

Read more GPSR info here: Terms of service (section 21)

Choose options